SINGLE PASS WEB PRODUCTION MULTI PASS SHEET PRODUCTION

VS

MULTI-PASS SHEET-FED PRODUCTION

EXAMPLE FOLDING CARTONS

● Printing front and back

● Foiling

● Laminating

● Varnishing

● Personalising/numbering

● Verifying/100% inspection

● Embossing/braille

● Creasing

● Perforating

● Die-cutting/sheeting or rewinding

This would first be printed on an offset printer or a digital printer such as an HP Indigo, the design would be printed onto the substrate. It would then be taken o that machine and printed on the back if required or stored. Then it would be taken to a finishing machine to have either laminate or cold foil (silver effect) applied. Once laminate applied and

cured, this generally needs time to “set”, it would then stored again. You may then apply a varnish (gloss or matt) Then it would be taken to a die cutter and cut out into the shape for the package, embossed for braille. This requires a large amount of time and effort to achieve a final product. Generally offset or sheetfed printing provides a much finer, high-quality print, however, the cost of production is much higher.

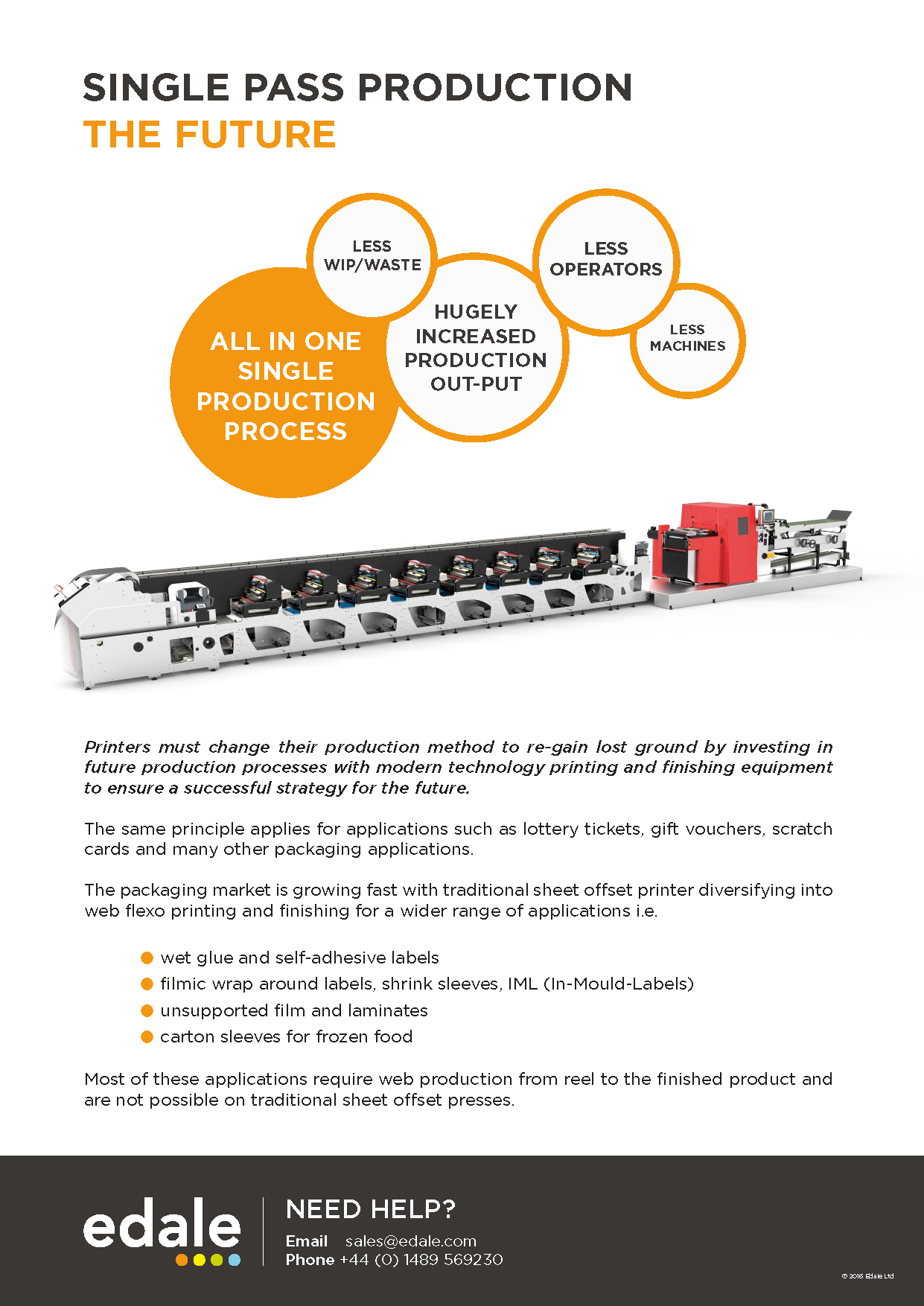

The substrate is loaded on one end of the machine on the unwind, the operator has set the registration settings and pressure and Inking settings which can be pre-programmed. The substrate is sent through the web transport. It is printed on the top and then a turn bar can be used to flip the substrate over and print on the back. Varnish, cold foil and laminate can also be applied on the same pass on separate print stations. It can then be embossed, and die cut through our Flatbed die cutter. What comes out the end is a whole finished product ready to be checked and packed.

The single pass method can remove the need for multiple operators and can be done much quicker. However the print quality may be slightly less, there are methods to increase the quality such as advanced sophisticated registration camera systems, however, these are a high investment. However the process is significantly shorter and in the long run, save costs. Also, a wider range of substrates can be used such as unsupported film.